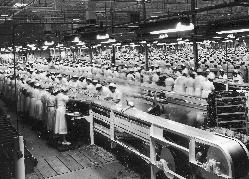

A Blur of Working Women

IN 1954, STAR-KIST OPENED ITS STATE-OF-THE-ART PLANT 4 tuna canning facility The 200,000 square foot plant had at its center a 43,200 square foot cleaning and sorting room.

FORMER CANNERY WOMEN ASSERT that the increased speed and technology of the operation did not substitute for human labor. Along ten 150ft-long steel conveyor tables, 800 cleaners could be working at one time and at least 100 more women served in quality control positions.

HEAR Mary Oreb discuss the cannery production and the process.

|

|

| At the new Star-Kist Plant 4, 1954. At conveyor belt tables, cannery women were a blur of activity. ~ The Star-Kist Story, corporate informational booklet, nd, c. 1962. Matich Family Collection |

|

|

|

| Van Camp Sea Food Company, nd, c. 1955. Using a knife with a five-inch blade with a solid wooden handle, women rapidly skinned the fish. ~ San Pedro Bay Historical Society |

|

| On the Cleaning Room Floor

MINIMUM REQUIREMENTS. Each woman on the cleaning line was responsible for four baskets of fish per hour. Depending on the size of the fish there could be one half to six whole fish in a basket. Women hand-packing cans needed to complete a 48 cans (1 case) per hour. With packing machines, women were responsible for four cases per hour.

HEAR Tina Ursich remember the minimum cleaning requirement

|

Making Connections

MANY EMPLOYEES TRAINED IN THE WETFISH PLANT - working with fresh sardine and mackerel kept wet during the canning process. Once in the tuna cannery, women were assigned their positions on the line by skill, not seniority.

CANNERY WORKERS RETURNED DAILY TO THE SAME POSITION. A sense of camaraderie grew along the lines. Former employees remember making tuna salad lunches together and supporting each other through difficult family times. One long time Star-Kist employee remembers sharing production overflow with women with large families.

|

|

| Sorting tuna loin at Van Camp Sea Food Company nd c.1955. ~ San Pedro Bay Historical Society |

|

|

|

|